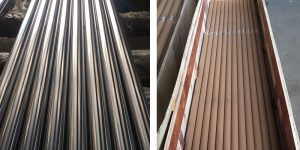

Cylinder piston rod is the important part in hydraulic cylinder built. The surface of the cylinder piston rod is one of the critical points in all hydraulic installations. An appropriate combination of base material and processing technology, along with the sealing system used in the corresponding hydraulic enviroment, is essential to optimize durability and cost-effectiveness.

Depending on the application, we advise on the most appropriate treatment and quality of materials in any given application.

Heat Treatment Type:

1) Normal no heat

2)Q+T(Quenched+Tempered)

3)Induction Hardened

- Quenching and tempering treatment

The purpose of quenching and tempering treatment is to make the piston rod have comprehensive mechanical properties with good matching of strength, hardness, plasticity and toughness, which is ready for subsequent surface quenching.

- Surface hardening

The piston rod moves frequently during the working process. Therefore, in addition to having good comprehensive mechanical properties to prevent deformation and fracture, the surface is also required to have high wear resistance. The surface hardness is required to reach 58-62HRC.In the production process, high-frequency quenching is often used.

- stress relief annealing

Because surface quenching uses the product’s own waste heat for tempering treatment, the tempering temperature is gradually reduced, there is no complete tempering heat preservation process. The tempering time is short, the stress relief is incomplete, and there are large residual stresses in some products. Therefore, the piston rod must be annealed before chrome plating to eliminate internal stress caused by grinding and surface treatment.

- Electroless nickel-phosphorus plating on the surface

In addition to hard chromium plating on the surface of the piston rod for hydraulic cylinders, the outer surface of the piston rod can also be electrolessly plated with nickel and phosphorus;

The surface of the cylinder piston rod with special requirements can also be thermal sprayed alloy or sprayed ceramic layer.